Energy saving and CO2 reduction, together with Heat Matrix

Up to 30 percent of industrial heat is lost through flue gases. Industrial residual heat can often be used in the same, or in a nearby process. This reduces the CO2 emissions and energy costs of your plant, while the payback period is often less than five years. Our sister company Heat Matrix is a specialist in industrial heat recovery.

Why recover heat?

- Industrial plants lose 10 to 30 percent of their heat through flue gases, baking vapour or drying air

- By putting this heat to good use, you can save between 5 and 25 percent on energy consumption and CO2 emissions

- Payback periods of 5 years or less are feasible

OUR GOAL

Help the industry become more sustainable

Does your business process produce flue gases, baking vapour or hot, humid air streams? If so, heat recovery can significantly reduce your CO2 emissions and energy costs. Our aim is to make your plant more sustainable, with minimal impact on your primary process. With this intervention, we help companies in the chemical, food and ceramic industries to become more sustainable and able to comply with applicable environmental requirements, laws and regulations.

KNOWLEDGE

In-depth knowledge of diverse industrial processes

Together with Heat Matrix, we have realised numerous successful business cases. Success was always predetermined, as we always start with our Heat Recovery Scan. This analysis maps your heat sources and heat users and identifies the most promising concepts for heat integration. As a result, you get instant insight into the investment costs, expected energy savings, CO2 reduction and payback period.

GUARANTEE

We guarantee your business case

After the Heat Recovery Scan, we will work together to formulate the best heat integration concept for you. Based on detailed analysis of your process data, we figure out what technology you need in the heat integration design. This eliminates the final uncertainties so you can make an informed investment decision. So before you green-light the project, we will both know exactly where we will end up after completion.

HEAT EXCHANGERS

Recovery of residual heat from flue gases

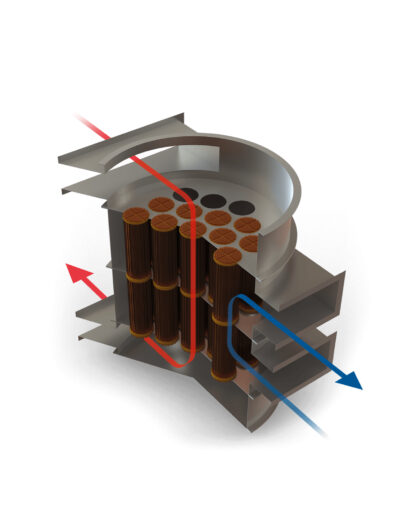

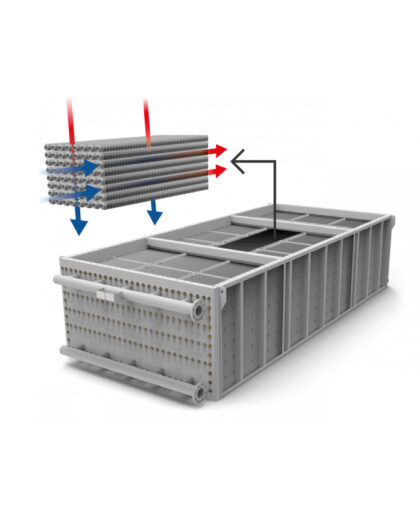

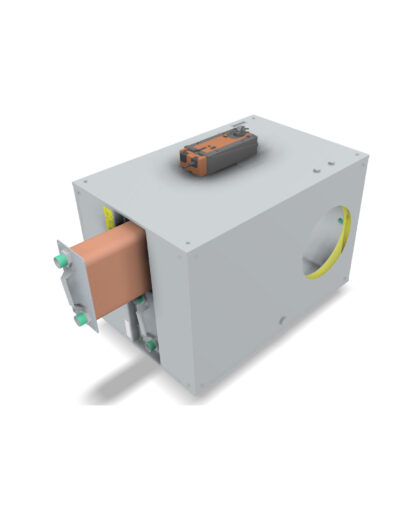

For residual heat recovery, we use heat exchangers that transfer residual heat to cold air streams (gas/gas heat exchangers) or heat exchangers that transfer residual heat to cold water or thermal oil (gas/liquid heat exchangers). The composition of the flue gas determines what material the heat exchanger is made of: steel or polymers. For corrosive or highly polluting flue gas, we opt for a polymer heat exchanger.

Gas/gas heat exchanger for efficient heat recovery

An air preheater is a gas/gas heat exchanger that recovers heat from flue gases, baking fumes or drying air to preheat process, drying or combustion air. The heat is integrated directly into the process, providing efficient heat recovery in steam boilers, oil boilers, dryers and furnaces.

Heat recovery from flue gas at high temperatures

An economiser is a gas/liquid heat exchanger that recovers heat from flue gases or exhaust air from a dryer or furnace to preheat liquids for the primary process. The economiser is used for flue gases above 150°C and can also be used for building heating or cleaning processes.

Heat recovery from flue gas at low temperatures

A condenser is a gas/liquid heat exchanger used with flue gas or drying air temperatures as low as 80°C. This heat exchanger recovers energy from flue gas or drying air at a relatively low temperature, condenses water vapour to liquid and recovers both tangible and latent heat. The energy can be used to preheat process water or as input for a heat pump.

Profitable heat recovery for the food sector

Bos Nieuwerkerk is the exclusive Benelux partner of Exodraft, manufacturer of gas and liquid-heat exchangers. Thanks to their modular design, they are easy to install and scalable. They make heat recovery profitable for the food sector, with minimal process interruption. The recovered heat can heat buildings or water. The solution has more than proven itself in bakeries.

We create concepts for heat recovery and supervise implementation. It is a thrill to see a good idea executed well.

Rik Kuenen, project engineer

APPROACH

Four steps to sustainability

Our process comprises four steps that allow us to achieve heat recovery from flue gases properly, quickly and cost-efficiently. You are completely unburdened throughout the process. Your dedicated account manager and a dedicated team guarantee advice, design, production, installation, implementation, validation and warranty.

Step

Heat Recovery Scan

With the Heat Recovery Scan, we make a thorough analysis of your entire heat economy. This serves to map your savings potential and present an indicative business case.

- Residual heat source analysis

- Residual heat consumer analysis

- Promising heat recovery concepts

- Not a thick and expensive report, but compact advice

Step

Heat integration design

In this step, Heat Matrix’s expertise in heat recovery and Bos Nieuwerkerk’s expertise in flue gas systems come together. We analyse the process data to select the heat recovery technology and determine the savings potential.

- Process diagram for heat integration concept

- Application in your existing installations

- Minimal impact on your current primary process

- Final business case and quotation

Step

Realisation of heat recovery system

The heat recovery system is manufactured and installed under the supervision of our own engineers. We take care of the overarching project management.

- No handovers between different parties

- Grip on planning and quality of execution

- We test the installation ourselves

- We guarantee the performance

Step

Service

After delivery, we guide you through a successful start-up. This is where the payback period of your investment begins, as we guarantee the performance of your system.

- Advice on spare parts

- We call biannually for check-ups

- We can carry out periodic inspections

- We are always here for you

REFERENCES

What makes us proud? Our projects and our clients!

From paper manufacturer to beer brewer, from biscuit to brick manufacturer, we achieved significant savings in energy and CO2 emissions for numerous manufacturers.

Heat Matrix

Over 15 years of expertise in heat recovery?

Our sister company Heat Matrix has over 15 years of expertise in heat recovery. Thanks to our partnership, you get to work with one party, while benefiting from the expertise of two sister companies working for you in tandem.

Why Bos Nieuwerkerk/Heat Matrix

- In-depth knowledge of diverse industrial processes

- Insight into investment costs, energy and CO2 savings, and your business case

- Gas removal and heat recovery as a turnkey project

- Total unburdening during a proven four-step process

- A no-nonsense mentality

Contact

Are you curious about your savings potential?

Let us conduct a Heat Recovery Scan and gain insight into the most promising heat integration concepts. Please get in touch with Rik Kuenen.