Where our expertise comes to life

In 50 years, you accomplish a lot. From potato processors to producers of high-grade cocoa products, from refineries to water treatment plants. For a wide variety of process installations, we have delivered complete flue gas and heat recovery systems worldwide.

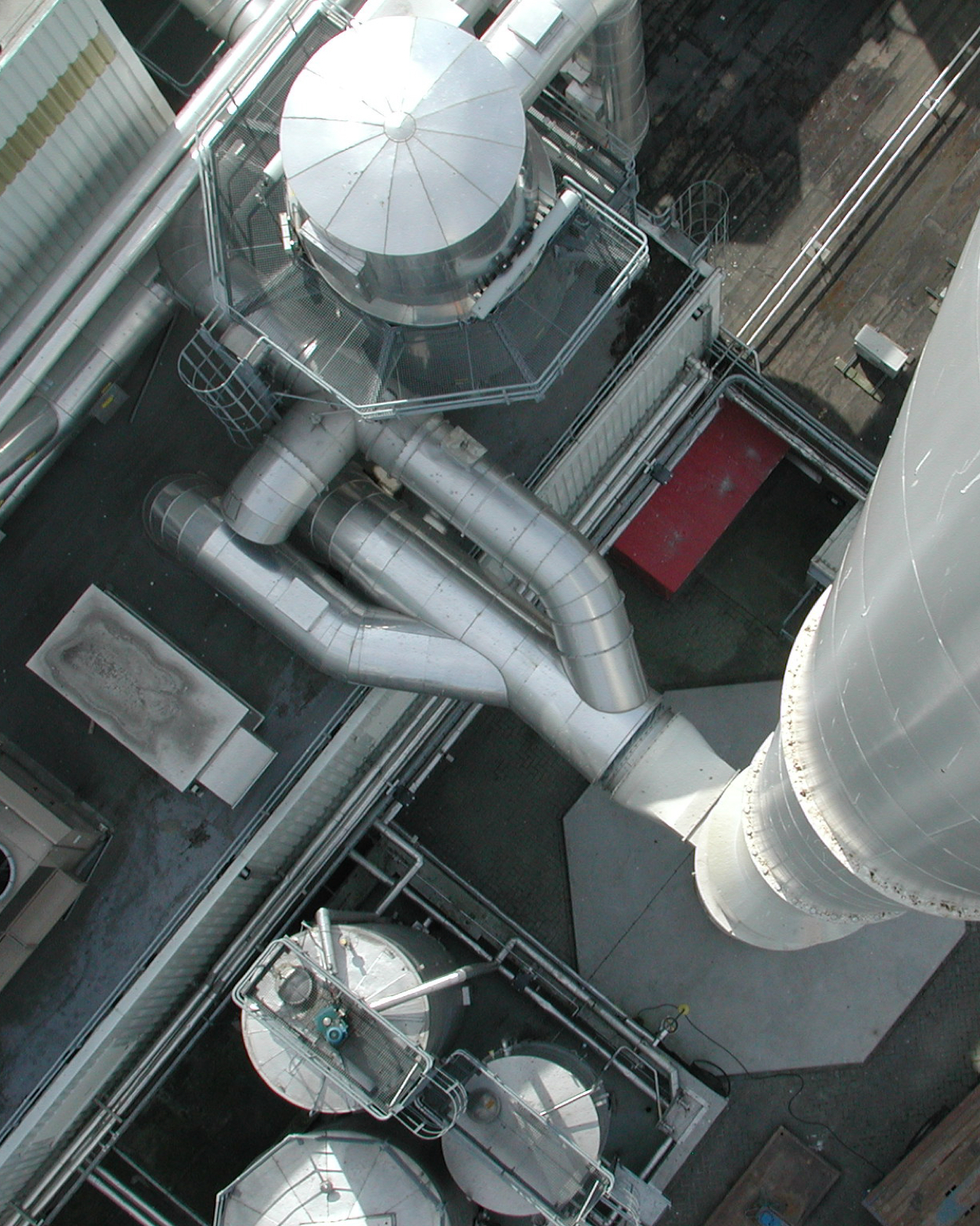

Effective process air extraction for a food factory

This international producer of frozen potato products supplies customers in more than 120 countries worldwide. The Tilburg plant needed numerous new exhaust air ducts to effectively remove process air. We designed and built a route that included a new collector and several new connection points.

Cocoa factory quickly got new chimney after fire

At the cacao factory of Olam (current name: OFI) in Wormer, a fire broke out that transferred to the chimney. We secured the chimney right away. By pulling out all the stops, we managed to complete a new chimney within 10 weeks, allowing the factory to be up and running again quickly. We also supplied new chimneys for the Olam factory in Koog aan de Zaan.

Chimney for Nuon Diemen

For Nuon’s power plant (now: Vattenfall) in Diemen, Standard Fasel was commissioned to realise boilers. The boiler specialist asked us to take care of the chimney. We designed and manufactured the chimney according to specifications and architectural requirements.

8% energy savings through heat recovery from dryer

Lubrizol Belgium, producer of CPVC, wanted to reduce the energy consumption of its drying processes. Together with Heat Matrix, we managed to use the corrosive flue gases to preheat the incoming air for the dryer from 10 to 56°C. This reduced their energy consumption by 170 kW, with no corrosion problems.

Constructing new Oerlemans chimney, extending existing one

Oerlemans in Broekhuizenvorst (now Lamb Weston) produces frozen potato products, with an emphasis on chips. We realised a new chimney for an additional production line, including all modifications to the ductwork. We also extended an existing chimney.

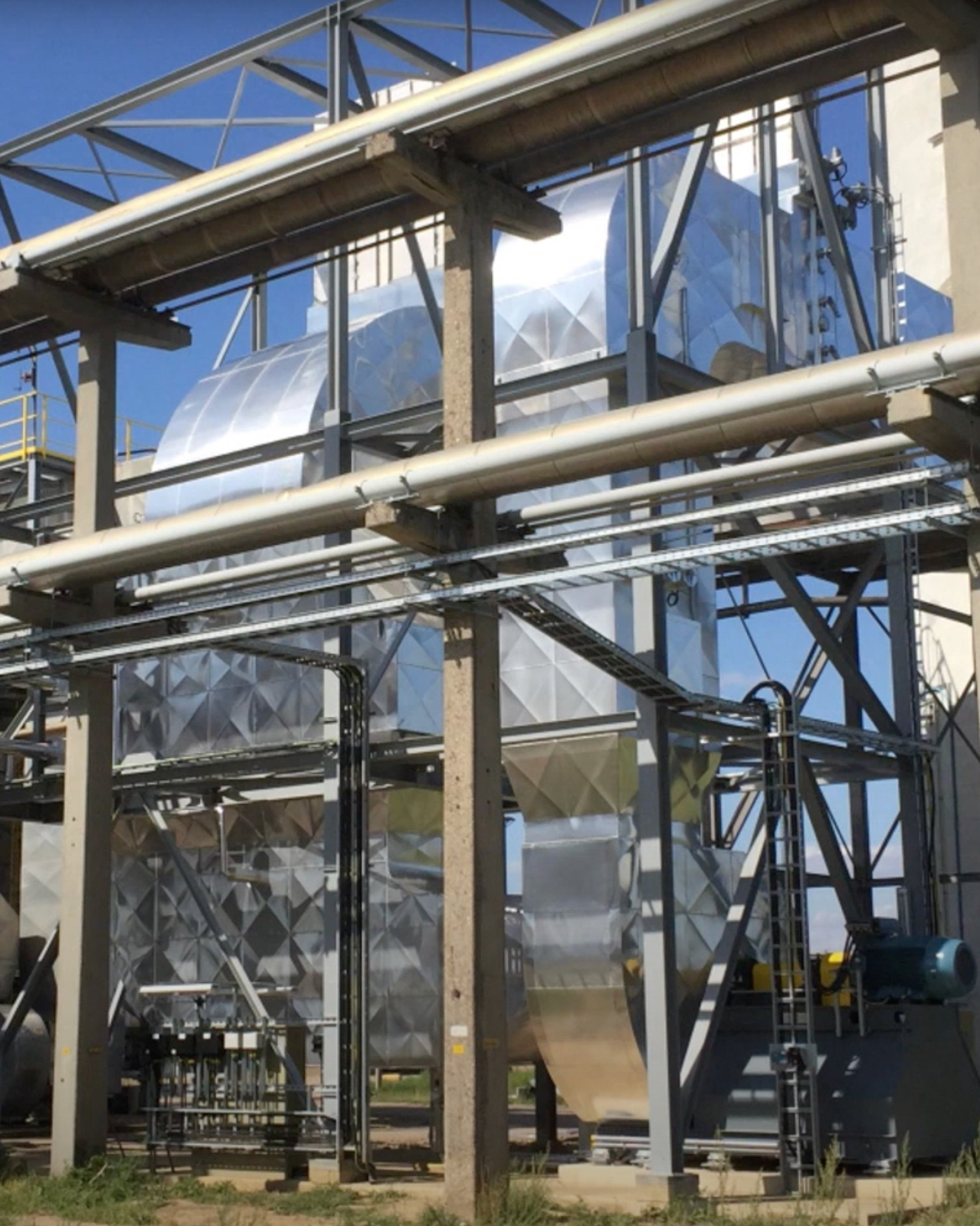

Chimneys for a heat grid

Eneco’s power plant in Zoetermeer wanted to supply heat to Zoetermeer’s Oosterheem neighbourhood via a heat grid. Croonwolter&dros engaged our expertise for the removal of flue gases through chimneys. To this end, we realised light flue gas ducts and supports in a steel structure.

4% more efficiency for a brewery’s steam boiler

For global beer producer Carlsberg, we realised a heat recovery concept from corrosive flue gas from the biogas-fired steam boiler. This system has an output of 290 kW and supplies the boiler with supply air preheated to 80°C. As a result, their efficiency has increased by 4%.

Complete process air extraction

Kraft Heinz in Elst produces ketchup and other products that require process air to be extracted and blown out through a chimney. We took care of the design, production and assembly of the chimney.

290 kW energy savings through heat integration on a dryer

Together with Heat Matrix, we managed to use Sonac Loenen B.V.’s 81°C hot flue gas from their dryer to supply the same dryer with air preheated from 10 to 52°C. Without corrosion or contamination problems, thanks to polymeric technology and an integrated cleaning system.

No odour in Etten-Leur

Hill’s Pet Nutrition Manufacturing in Etten-Leur produces pet food. Local residents complained of odour nuisance. The chimney arrangement we realised in a small courtyard put an end to the odour problems.

New chimneys for Fujifilm

Fujifilm in Tilburg produces photographic paper, membranes and filters for gas or water purification. We designed, manufactured and assembled new chimneys for effective discharge of their process air.

USG recovers 5.6 MW of heat from corrosive flue gas

For USG, Chemelot’s utility supplier, we managed to make the (corrosive!) flue gas from the incinerator usable. It heats the boiler feedwater of the steam network from 20 to 96°C. The system with a capacity of 5.6 MW provides significant CO2 reduction.

Better performance than required for GMB

GMB in Zutphen processes sludge that is dried and reused. This process releases moisture and a strong odour. We designed and built a 125-metre-high chimney that outperforms the permit requirements.

Chimney on minimal foundation in Botlek

Refinery Fluor Daniel and oil transfer company Esso Botlek needed a chimney on an extremely limited concrete foundation. We designed and built a chimney with a liner, in a steel frame. Within a very short lead time at that.

Fitting a chimney for Rijnvallei into a small space

At animal feed producer Rijnvallei in Wageningen, we faced the challenge of finding the right space for a chimney. Our solution was a steel frame with gable brackets for stability, absorbing extreme forces due to weight and wind.

Three 200-metre chimneys of a power plant constructed from below

The Isla refinery in Curaçao was renovating its power plant. The outdated concrete chimney needed a revamp as well. On behalf of Ballast Nedam, we built three new chimneys, each 200 metres high. They were mounted one by one from below and pulled up metre by metre, quite the technical feat.

Dutch Cocoa’s process air efficiently removed

Dutch Cocoa’s factory in Amsterdam produces high-quality cocoa products for chocolate, dairy and cosmetics. The challenge was the discharge of process air. We solved this issue by installing a duct network to a collector duct and a new chimney.

220t annual CO₂ savings for Aviko Rixona

Aviko Rixona wanted to reduce its CO2 emissions. Together with Heat Matrix, we identified heat recovery potential in the 170°C hot flue gases of the steam boiler. A polymer air preheater tackled the problem of corrosion caused by biogas. The repurposed heat saves 130kW and 220t of CO2 per year.

No more odour nuisance in Lisse

Vleeswarenfabriek Persoon in Lisse processes artisan meat for end consumers. We were able to eliminate odour nuisance from the production halls by installing new ductwork and a chimney stack with liners, allowing air to be blown out higher.

All discharge channels for new McCain plant

McCain is a potato processor for export. The Lelystad plant expanded with a new factory next to the existing one. We realised all ventilation and process air extraction ducts for the expansion.